2010 - F5J electro Perfect / Perfect ET

New electric "disser" electric Perfect or

Perfect ET makes incredible light weight electric sailplane.

Read more HERE

New Pike Perfect ET (Extended Tips) released

Vlastimil flew the new ET tips on Tuesday before the North

Cyprus F3J Open. and in the weekend Jojo won the North Cyprus

F3J Open 2009.

The new tips makes the Pike Perfect 3,78m and is made to improve

circling performance and dead air time. The weekends competition

shows that it is also performing well in both high winds with

ballast and normal conditions.

See some pictures from the first flights

HERE

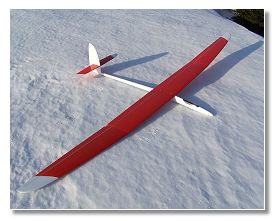

Pike Perfect is in production!

The first models have left the moulds and are now being tested.

This page will progress as we test more and within a week you will see a

complete article explaining how and why things become real.

The wing planform for the new all-round F3J-model Pike perfect can be

characterized as follows:

- Large wing area

- Nearly elliptical planform

- Moderate aspect ratio

- Deep chords for high Reynolds numbers

Setup and throws of model will be as usual right here on our page with

detailed settings for both pleasure and competition.

22/10 Larry flew the first 2,4 Perfect

Larry Jolly have flown the first 2,4ghz Pike Perfect.

Read his first thoughts

NEW

15/5 Instructions Perfect

Instructions on building the Pike Perfect is out

Download with pictures (2,2mb .pdf)

or without

pictures

(0,3mb .pdf)

8/4 Perfect start to new model

A Perfect start for our new model. In

the first competition we had 3 Perfect's in the finals and all

places on the podium were Pike's.

Eurotour F3J in Istanbul:

1. Philip Kolb, Pike Perfect

2. Colin Lucas, Pike Superior

3. Jo Grini, Pike Perfect

Some

words from Jojo - Read about Perfect

21/3 More photos by Jojo

Pictures HERE or visit his

diary

19/3 Philip back home

Read more HERE

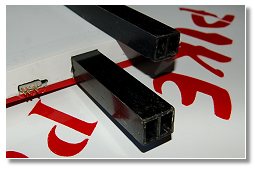

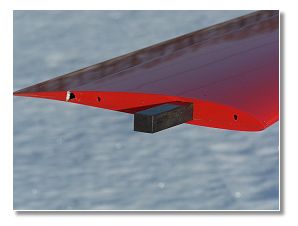

18/3 New joiner

mould ready

The first joiners were solid but we have now made new mould and

saved 17g on each joiner. The new joiners are hollow and weighs 18g

each. That is a total save on 34g. It probably sounds little but

this is out in the tip and makes a difference. We have tested and

they are even stiffer than the first we made!

14/3 Hello out

there!

We are still alive and flying. We spent three more days

experiencing calmer air. Unfortunately it was again far away from

floating conditions.

Read more HERE

Technical:

Wingspan: 3550mm, Length: 1625mm

Wing area: 74,93dm, Tail area: 7,81dm

Aspect ratio: 16,81

Wing section: PK-91A - PK-91B - PK-92 - PK-93 - PK-94

Tail section: HT-14 - HT-13

Weight: Apx. 2050-2300g depending on lay-up

SL - 68 - 68/80 - 80 - eXtreme

Design by Philip Kolb

|

New Pike Perfect ET (Extended Tips) released

See some pictures from the first flights

HERE

Larry Jolly have flown the first 2,4ghz Pike Perfect.

Read his first thoughts

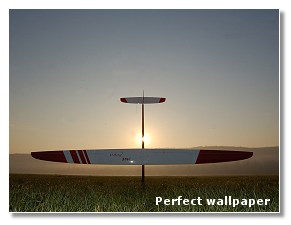

Download wallpaper (click to open and

then right click and "use as background").

New joiner mould ready

Each joiner is 18g!

And STRONGER than full carbon standard

Read Philip's first days of flying

with Pike Perfect HERE

A close up reveals that this is a

Samba model. Everything fits Perfect

and is well thought out. |

Electro fuse |

Tip & tricks | Antenna

solution

| 2,4Ghz installation

|

Setup |

Throws |

Howto |

More photos

|

| Neutral elevator |

Instructions with pictures (2,3mb .pdf)|

Instructions

without pictures (0,3mb .pdf)|

|

Color design |

Pike Perfect

The Quest for the Ultimate F3J-Model

High quality moulded glider designs now dominate the F3J Class. The F3J pilot

has to decide which one of the many excellent models currently available he will

use in competition. The majority of these models offer excellent performance

potential, and are built to the highest standards now expected for competition

F3J models.

Writer of this article. Philip Kolb with his Pike

Superior and Pike Perfect

So what keeps designers and constructors trying hard to push

the limits and expending their energy on new designs? Is there still potential

performance to be had in the evolution of F3J glider design? Is it worth the

time and effort to design a new glider with so many excellent moulded models

already available?

Considering the gliders flown at the F3J World Championship in 2004 it is

interesting that the majority of pilots have embraced the strategy of utilising

two different designs to cope with various weather conditions. Usually a large

and light glider is used for floating conditions expected in the morning or

evening rounds. However, an agile and stiff model capable of being ballasted is

desirable in “launching and landing” conditions, or where there is windy and

turbulent weather, a heavier and more agile design offers the best potential for

the winning solution.

Pilots choosing one design will find it challenging to adapt to all conditions.

One strategy is to choose a design that handles well in normal conditions and

then carefully lighten the structure to cope with the dead air rounds. This

strategy can prove difficult as the lighter model may not handle as well with

the lighter wing loading, and may prove structurally deficient when the

competitor attempts to add ballast for normal conditions. Very often these

pilots have to admit that there are other models better suited for some

conditions and they find themselves at a disadvantage. A pilot who chooses to

fly the optimal model for the air present in a particular round may be

frustrated by the 3 model rule if he is unlucky enough to damage a given model

and find his other optimised models not suitable for the conditions encountered

in later rounds.

So it is obvious that the real challenge is to design and construct a new model,

which will offer the best performance, over a maximum range of conditions. Some

try to continue the evolution of an existing design, step by step, fixing each

problem as they are encountered. One popular example is to increase the wingspan

and wing area. This method is widely accepted and is helpful, especially when

changes need to be made to optimise a heavy model for lighter conditions.

Performance improvements can be expected up to a certain point, but in the end,

the performance gains will be marginal. These changes can have unexpected

results, sometimes adversely affecting the performance of the original design. A

change in wingspan for example will have effects on the tail moment arm, tail

volume, and lift distribution of the wing. Therefore a complete new design can

offer more favourable results, versus redesigning parts on an existing model.

This is the principal I embraced while designing the Pike Perfect

The new model was designed to be the next step, combining both the floating

abilities of the large and light F3J gliders, and the manoeuvrability and

launching capabilities of the smaller ones. It is designed with the expectation

that no sacrifices have been to the handling qualities of the model. Experience

shows that this point is paramount; especially in difficult conditions, when

handling qualities prove more important than theoretical performance. These

thoughts have led to the design and development of Pike Perfect shown in the

following lines and figures.

The geometric design of the wing:

Designing the optimal wing planform, lift distribution, aspect ratio, and the

local Reynolds numbers were considered paramount for achieving the desired

performance. All of these parameters affect each other, and the designer must

make concessions so that the performance goals are achieved. The lift

distribution was the first parameter defined because of its fundamental effect

on performance.

The circulation is proportional to the local lift at the local chord. As a

result the maximum circulation will be at the root chord of the wing, where the

lift and chord are maximum. To minimize the induced drag of the wing, the

circulation has to decrease elliptically along the span, towards the tip of the

wing. Building an elliptical tapered wing offers the advantage of a relatively

low tip volume and thereby lighter weighted tips, which helps to keep the plane

agile. Conversely, Reynolds numbers will get very low with narrow tips, which

increases the airfoil drag, and even worse, will have effects on the stall

characteristics of the plane, thereby inducing tip stall problems if the tips

are too narrow. The cl_max at the tip is reached earlier than the cl_max at the

root. In this case the choice will be a slightly over elliptical planform. The

25% chord line is kept straight in the centre of the wing to keep the torsion

forces as low as possible and is swept back at the tip. The hinge lines (75%

chord) of the flaps and the ailerons are straight to have identical depth of

flaps all over the wing.

The next parameter of interest is the aspect ratio. An F3J model will primarily

fly at relatively high lift coefficients, as compared to a speed model. The

proportion of the induced drag to the entire drag will increase with the lift

coefficient, so trying to reduce the induced drag is the way to go. Utilizing an

elliptical planform is a good start, but greater performance gains can be

expected by increasing the aspect ratio. Increasing the aspect ratio to reduce

the induced drag can be achieved by increasing the wingspan or reducing the

chord depths of the wing. Considering these facts it became apparent very soon

that a small model would have disadvantages compared to a bigger one. Either the

induced drag is relatively high because of the low aspect ratio, or a high

aspect ratio on a small plane can only be made by building a narrow wing, and

accepting the losses in airfoil drag and performance due to low Reynolds

numbers.

Faced with these design parameters, it was obvious that it would be necessary to

build Pike Perfect as a relatively large glider, with about 75dm˛ of wing area.

The aspect ratio should be about 17 to keep the induced drag low and the

Reynolds numbers high. Higher aspect ratios, as flown on several big gliders,

have proven to decrease induced drag. If the aspect ratio is too great, the roll

rate will decrease and agility will be lost.

The handling of the model must be preserved, so that low altitude “saves” are

possible. In conclusion, the wing planform for the all-round F3J model Pike

Perfect, can be characterized as follows:

- Large wing area

- Nearly elliptical planform

- Moderate aspect ratio

- Deep chords for high Reynolds numbers

Airfoil:

Modern F3J gliders are equipped with new airfoils developed utilizing computer

programs with calculation capabilities. One of the latest inventions in the

model airplane scene is the use of an inverse design tool for developing and

optimising airfoils. It is able to design the span wise airfoil transitions for

the entire wing.

The most popular and readily available tool is the ISES-Code based

Xfoil-Programme by Dr. Drela. This is a 2D-Solver for calculating airfoil and

boundary layer parameters. With the fully inverse design mode .mdes of the

Xfoil-Programme you have the opportunity to design and modify directly the shape

of the velocity distribution and thus the boundary layer parameters and thereby

the geometric shape of the airfoil. Most of the popular F3J gliders are equipped

with a single airfoil for the whole wing, which is perhaps slightly modified in

thickness. For Pike Perfect a non-linear airfoil transition was developed to

achieve maximum performance with a minimum of airfoil drag at the most important

speeds of flight. For several wing sections the airfoils were optimised for the

respective Re*sqrtCl. It is important to pay attention to the zero lift angles,

the momentum of the airfoils, and the characteristics of the Cl/a

- curve are not varying very much between the sections. I think Dr. Drela and

Frits Donker Duijvis were the first to understand the importance of this concept

for model airplane design.

The most important demands on the airfoils are:

- to provide a wide maximum of gliding ratio up to 20 m/s speed.

- a high cl_max for carrying weight in windy conditions and for “pulling g´s” in

tight thermal turns.

- a reasonable thickness for lightweight, strong, and stiff wing structure.

Tail and fuselage:

The cruciform tail has become a standard in F3J, although it has more surface

drag and usually a little more weight than using a V-tail. These disadvantages

quickly disappear when a proper sized cruciform tail yields a powerful rudder,

which is handy for tight and accurate circling. Besides, an all-moving elevator

will make dealing with the angle of incidence very easy. All in all, the

cruciform tail seems to be the best choice of tail configuration because of its

easy handling.

Nevertheless, the size, aspect ratio, tail arm, and section of the tail need to

be considered as important factors for the stabilization of the plane. The

higher the aspect ratio of the rudder and elevator, the steeper the Cl/a-curve

will be. With increased aspect ratio, the stabilization factor will increase.

Again, to avoid too high airfoil drag on the rudder and elevator, the aspect

ratio should not approach extreme values. Using modern airfoils, which will

still work fine at Reynolds numbers below 40k, aspect ratios of 7.5 for the

elevator and 3 for the rudder are achievable. The HT-airfoils designed by Dr.

Drela have shown to be relatively dragless at low Reynolds numbers with no

dead-band around the zero-lift angle. Both, elevator and rudder of the Pike

Perfect are sectioned with a transition from HT-14 at the root to HT-13 at the

tip. To avoid additional drag at the tail, the elevator is assembled very

tightly to the rudder, with its leading edge being joined and taped together in

front of the rudders leading edge. With this type of assembly, the gap between

the elevator parts and the rudder is kept minimal, and no triangular cutouts in

the trailing edge of the elevator are necessary to enable the full deflection of

the rudder. To provide enough elevator control, especially with fully set crow

brake in the landing approach, the elevator area chosen is a little larger than

theoretically necessary.

For precise landings, a down swept nose of the fuselage will help to slow down

the model, immediately after the touch down. The nose kink of the Pike Perfect

is 5° relative to the root chord centerline. The nose is reinforced with

additional carbon layers and has only a small canopy, which does not weaken the

fuselage structure, so hitting the landing target doesn’t damage the model. The

fuselage surface is kept very smooth to avoid additional drag. A very thin tail

boom diameter is hard to construct when stiffness and light weight are

paramount, so concessions in favour of a light fuselage were made by enlarging

the diameter to a reasonable proportion of strength and surface. Finally these

dimensions of the fuselage provide a better grip to control the plane under

great line tension before the start of working time.

Philip Kolb 2005/2006

English rewriting: Larry Jolly

Copyright Samba model 2006