Tips and tricks of the trade!

Here is a few tips and tricks on how to assemble a Pike

model. They will not help you win a contest but will make your model just

slightly more flush and practical.

Battery:

We recommend 2+2 NiMh, 2+3

NiMh or for the latest models the space is very limited so a 1+1 Liion

(panasonic 18650B or similar) is very suitable. Remember to check what

voltage the servos need. Only HV (HighVoltage) servos can do the 2cell Liion

that fully charged can be 8,2-8,4V.

Switch:

We strongly suggest a high amp switch as the

current with 6 digital servos might be above 8A in the zoom.

|

Fuse: Fuse:

The rods needs to be soldered to the supplied

threads and links. It is also possible to insert threads into the rods and

solder (see picture). This can also be glued but we recommend soldering with

atleast 150watt.

We strongly recommend as strong and fast elevator servo as you can. This

will help you get a fast and accurate zoom.

To be sure a good connection of the Dsub connector it is advisable to

connect to the wing and attach with a small amount of glue. This way the

distance will be perfect. |

Wing:

The servo wells have preinstalled carbon were

the servos are to be glued. This carbon and servo case should be rubbed so

the servos does not come loose. If one have access to frames this is a very

good solution and makes it easy to change servos if needed.

One can also join the top and bottom skin with balsa or similar. This will

make the seating for the servo much stronger and will result in less slop.

The tips and midsection should have a layer of tape so the paint does not

wear.

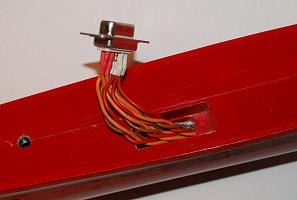

D-sub:

D-sub:

With all Pike models there comes a D-sub. This connector

supplies the wing with signals and power for the wing servos. It can be

connected in many ways but here are an example of how it can be used.

The plus and minus (+/-) are for all 4 servos so you need to connect 2

servos for each pin. Be careful and check several times before you connect

power to the system. If you have done it wrong you can make damage both Rx

and servos.

Joiner box fitting:

At the end of the joinerbox there is a lot of epoxy/micro balloons. Since

the fitting of the joiner box is extremely tight it is possible to break of

some pieces of the joiner box ends. To avoid this it is normal to cut of

some of the micro balloons with a knife as the picture shows. One can also

sand/rub a little bit the opening (the last few millimeters).

Elevator

fitting:

Elevator

fitting:

Ever

wondered if elevator will keep that tight fit on the joiner ? Well it might

not. But if it gets a litle loose here is how you make it tight again. There

are two solutions:

1. Rub a candel light against the joiner. Or cross country ski wax.

2. A few milimeters from the end of the joiner you use

your knife to make a small cut. This cut will raise the carbon fibers

slightly and keep that tight fit.

On the Pike Perfect you use a small piece of tape on the front of the

elevator.

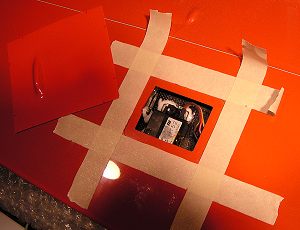

Servocover:

Servocover:

Have you ever wondered how

those servo covers are so neatly cut ? They could be cut at Samba but then

your servo would have to be on the correct place. Maybe you want the servo

to be glued as close as possible to the spar. Or conveniently in the middle

of the cut-out hole.

- Start with gluing the servo in or even better glue in a servo frame so

that the servo can be taken out for changing of gears etc. Be sure to adjust

the servohorn position before you glue the servo in.

- Tape the outlines of the servo cut-out with a masking tape (or any cheap

tape you have handy).

- Place the servocover were it fits the servo arm and mark the outlines on the

servocover with a pen.

- Cut the servocover at the marked lines and make the corners round.

- The servo cover is then taped in place by a clear tape.

Servotravel flap:

The Brio wing is very thin and with huge

flaps but will manage a Graupner DS368 (or JR) and the new digital MicroMaxx

X (or Xp) if the servos are placed towards the spar. And still one will be

able to get 90 degree travel. If one can get the servoe more backwards it is

even easier to get good travel.

Alternative servos might be Futaba 3150, Graupner DS161, Hitec 5125MG or

Volz WingMaxx digital.

Extreme use of servo:

Sometimes and with some radios we like to use

the full potential of the servo. But if we use a clevis it will rub against

the servo shaft. If one looks at the clevis it is mostly one side that have

full support of the forces. The other side can be grinded down to let the

servo shaft have room.

This way we use the full potential of the servo with very little slop yet

still all the movement we need.

Now get out flying!!!